DEMONSTRATION OF THE CHLORINATION IN GENERAL

In this chemical treatment Cl2 (Chlorine) Gas will be feeded in the drinking water.

Chlorinator is a special device, that can provide a continuous and constant supply of metered chlorine in the safest way.

The chlorinators of Ecoviz Kft find application in drinking water treatment, cooling water treatment, wastewater treatment, bleaching, pharmaceutical formulations and other industrial applications.

Depending upon the mode of operation, all parts of the Vacuum-Feed Gas Chlorination unit are operated by the help of the Vacuum, Thereby, in case of leakage only air would escape from the system instead of the dangerous chlorine gas.

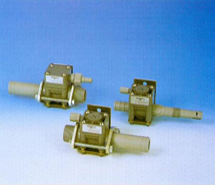

The switchover module works automatically and also vacuum-operated. There is no manual reset required and an empty Cl2 container can be replaced with a full one, providing a continous chlorine supply. This commutator valve is a spring loaded toggle design and shall not require field adjustment to place in operation.

WEDEGAS gas detector is an additional safety equipment and is recommended for sensing and alerting Chlorine gas escape in the chlorine dosing and storing area.

In order to keep the chlorine values prescibed by the law in the drinking water, the chlorine dosage of must be adapted accordingly to the quantity of water and the chlorine consumption.

An automatic chlorine dosage can be conducted after the quantity of water, after chlorine surplus or according to both criteria. A condition for the automatic

chlorine dosage after the chlorine surplus is the precise measurement of the chlorine content.

The chlorinator is convertible to automatic control by insertion of a motorized control valve in the vacuum line to receive a signal from appropriate control equipment. The efficient and satisfying work of an automatic chlorinator depends on reliable, continuous and enough sensitive chlorine measurement.

We are fabricating our ADVANCE® 200 type gas chlorinators for 25 years, expert engineering and carefully testing assure years of satisfactory operation, correct installation and proper care will insure the best operation and minimum maintenance. They are constructed of the finest materials available for the chlorine service and disposing of complete authorisations , certified by the Hungarian Water Authority, on the basis of inspections and analyses of VITUKI RT.

The dosing range our devices: 0,6 g Cl2/h - 150 kg Cl2/h (in 14 stages)

|

|

Vacuumregulator | Rotameter |

|

|

| Selector switch | Injector |

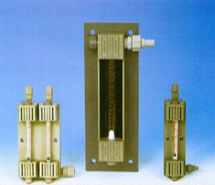

Main elements of the chlorinator: The vacuum-regulator the injector, and accordingly between these two units the rotameter and the feeding valve. If the separate rotameter of a chlorinator is also supplied with a feeding valve, we call it remote controller.

In the compact gas feed systems, the rotameter and the manual dosing valve are built together.

We are providing our equipments with various accessoires in order to ensure the extensive applicability.

With the dosage of other gases, please multiply the following counters:

SO2 --> 0,95; NH3 --> 0,5; CO2 --> 0,78

The minimum dosing capacity is 5% of the maximum value with all types.

For simpler operations and controllableness, our remote controlled devices are suitable; for continuous operations the automatic switchover devices are recommended.

The chlorination into more than one dosing points does not cause any problem for our devices. The systems are designed modularwise so all kinds of expandabilities are later possible.

We produce ADVANCE® 200 type of dosing devices for watertechnology, Food industry, viticulture and other applications of various gases like: NH3, SO2, CO2

AUTOMATIC CHLORINATORS

Devices up to 10kgs/h are equipped with an automatic regulator for controlling the remainder-free available chlorine content, but all types without exception can be automated posteriorly. Each elements of a manual remote controlled equipment can be replaced on elements of the automatic system.

Capacity selection of the automatic chlorine dosing plants in 6 stages:

| Type | Max. Capacity [g/h] | |||||

|---|---|---|---|---|---|---|

| 201C*-a | 200 | 500 | 900 | 2000 | ||

| 202C*-a | 4000 | |||||

| 203C*-a | 10000 | |||||

* available variations, identified with 3 or 5

The minimum dosing capacity is 10% of the maximum value with all types.

Types of ADVANCE Devices

2 0 X Y Z

|

X

Identification of the max. Capacity (for chlorine gas) |

Y

Alphabetic character of feed gas types |

Z

Mounting method of the vacuumregulator |

|||

|---|---|---|---|---|---|

| 1 | 2000 g/h | A | Ammonia | 1 | With regulator valve on the chlorine bottle or on the collector pipe |

| 2 | 4000 g/h | B | Carbon dioxide | 2 | With regulator valve on the chlorine barrel |

| 3 | 10 kg/h | C | Chlorine | 3 | With remote controller on the chlorine bottle or collector pipe |

| 4 | 20 kg/h | D | Sulphur dioxide | 4 | With remote controller on the chlorine barrel |

| 5 | 40 kg/h | 5 | With selector switch on the chlorine bottle or collector pipe |

||

| 6 | 75 kg/h | 6 | With selector switch on the chlorine bottle |

||

| 7 | 120 kg/h | |

|||

The structure of ADVANCE devices

The devices identified with 200, are almost the same, considering their functional principle and construction. The difference between each types is the mounting method, the capacity of the vacuumregulator, sizing and accordingly the materialstructure depending on the type of feed gas. All chlorinators of the ADVANCE 200 family are closed designs and working on the basis of the vacuum principle.

The working principle is that the chlorine gas will be transported from the chlorine bottle under the atmospheric pressure (Vacuum) until the dosing point. Vacuum prevails in all elements of Sytems (except chlorine tanks), as well as all chlorine pipes, which arises in the the injector functioning ont he basis of the Venturi nozzle. So, in case of a defect in liquid tightness or a damage in the pipeline, air will get into the system, (instead of chlorine gas in the environment)

At the same time, or when the vacuum stops due to any reasons, the safety valve from the vacuum regulator will close the bottle, and no moree chlorine gas molecule can enter in the dosing system.

| Type | Max. Dosing capacity [g/h] | Max. Dosing capacity [kg/h] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 201 | 12 | 28 | 75 | 200 | 500 | 900 | 2 | |||||||

| 202 | 200 | 500 | 900 | 2 | 4 | |||||||||

| 203 | 10 | 204 | 20 | |||||||||||

| 205 | 40 | 206 | 75 | |||||||||||

| 207 | 120 | 208 | 150 | |||||||||||

| Designation | Type | |

|---|---|---|

| Gas detector | ECOGAS | details >> |

| Gas detector | ECOGAS-2 | details >> |

| Residual chlorine analyser | ECOMETER | details >> |

| Automatic dose control unit | ECOMAT | details >> |

| Chlorine gas flowmeter | ECOFLOAT | details >> |

Several types of chlorinators

|

|

| ADVANCE 201 | ADVANCE 201 - mounted on the collector tube |

|

|

| ADVANCE 205 - mounted on the collector tube | ADVANCE 205 |